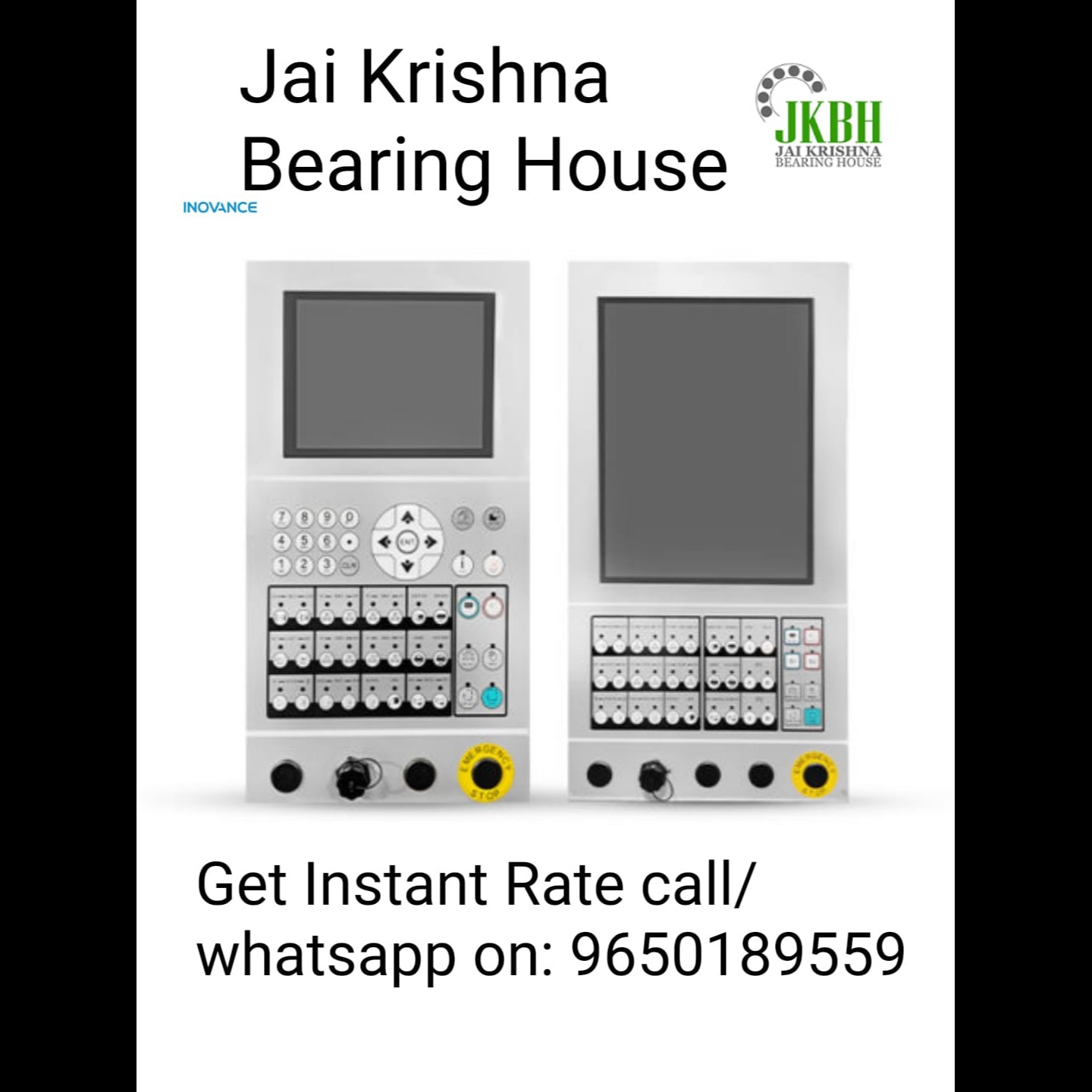

**Inovance** is a company known for producing a range of automation products, including controllers for various types of machinery. They manufacture controllers used in industries such as injection molding, packaging, and more. Specifically, when it comes to **injection molding machine controllers**, Inovance offers solutions designed to manage and optimize the operation of injection molding machines. Here are the key details you would typically find in an **Inovance Injection Molding Machine Controller**: ### Key Features of Inovance Injection Molding Controllers: 1. **Multi-axis Control**: - Injection molding machines often require precise control over several axes (e.g., screw rotation, injection pressure, clamping force). Inovance controllers are designed to handle these movements efficiently with high accuracy. 2. **User Interface**: - **HMI (Human-Machine Interface)**: Inovance provides user-friendly interfaces on their controllers. Operators can easily interact with the machine via touchscreens to control settings such as cycle times, injection pressure, temperature, and other parameters. - These HMIs often allow for real-time monitoring of machine parameters, providing insights into machine health and performance. 3. **Advanced Control Algorithms**: - Inovance controllers typically integrate advanced control algorithms to ensure stable operation of the injection molding process. These algorithms optimize the injection process for better quality, less material waste, and reduced cycle times. 4. **Real-time Data and Monitoring**: - Real-time feedback is provided to operators on key parameters like injection speed, mold temperature, injection pressure, and clamping force. This helps to ensure consistency and quality in the products being molded. 5. **Energy Efficiency**: - Modern Inovance controllers often focus on optimizing energy usage. They can adjust the machine’s power output based on real-time load, improving energy efficiency and reducing operational costs. 6. **Connectivity & Integration**: - Inovance injection molding controllers often support various industrial communication protocols, such as **Ethernet/IP**, **Modbus**, or **Profinet**, allowing easy integration with other devices and centralized monitoring systems. - Some systems support IoT (Internet of Things) capabilities for remote monitoring and diagnostics. 7. **Safety Features**: - Injection molding machines require high safety standards, especially because of the risks posed by high-pressure hydraulic systems and moving parts. Inovance controllers typically come with built-in safety features such as emergency stop functionality, overheat protection, and more to protect both the operator and the machinery. 8. **Customization and Flexibility**: - Many Inovance controllers offer customizable settings and programming options, allowing manufacturers to tailor the machine’s operation to specific molding processes. This can include setting different modes (e.g., automatic, manual, or semi-automatic) for various stages of the molding cycle. ### Common Models of Inovance Controllers in Injection Molding Machines: - **DVP Series PLCs**: Often used in injection molding applications, these programmable logic controllers (PLCs) are known for their flexibility, ease of use, and reliability. - **Inovance HMI Models**: HMI interfaces by Inovance allow for easy interaction with molding machines. They often feature large screens for visualization of machine parameters and process control. ### Application Benefits: - **Improved Production Efficiency**: Optimized injection cycles reduce downtime and improve throughput. - **Enhanced Product Quality**: Real-time feedback and precise control parameters ensure consistent molding results with minimal defects. - **Ease of Maintenance**: The system can alert operators about potential issues, minimizing unplanned downtime and ensuring preventative maintenance. ### Conclusion: If you\'re working with an **Inovance injection molding machine controller**, you’ll be benefiting from an advanced automation solution designed for efficiency, safety, and precise control. The controllers are highly customizable, making them suitable for a wide range of injection molding processes. You’ll likely find various options for monitoring, data collection, and connectivity, which are essential for maintaining high-quality production while also minimizing energy consumption.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2025-01-24T09:32:36

**Inovance** is a company known for producing a range of automation products, including controllers for various types of machinery. They manufacture controllers used in industries such as injection molding, packaging, and more. Specifically, when it comes to **injection molding machine controllers**, Inovance offers solutions designed to manage and optimize the operation of injection molding machines. Here are the key details you would typically find in an **Inovance Injection Molding Machine Controller**: ### Key Features of Inovance Injection Molding Controllers: 1. **Multi-axis Control**: - Injection molding machines often require precise control over several axes (e.g., screw rotation, injection pressure, clamping force). Inovance controllers are designed to handle these movements efficiently with high accuracy. 2. **User Interface**: - **HMI (Human-Machine Interface)**: Inovance provides user-friendly interfaces on their controllers. Operators can easily interact with the machine via touchscreens to control settings such as cycle times, injection pressure, temperature, and other parameters. - These HMIs often allow for real-time monitoring of machine parameters, providing insights into machine health and performance. 3. **Advanced Control Algorithms**: - Inovance controllers typically integrate advanced control algorithms to ensure stable operation of the injection molding process. These algorithms optimize the injection process for better quality, less material waste, and reduced cycle times. 4. **Real-time Data and Monitoring**: - Real-time feedback is provided to operators on key parameters like injection speed, mold temperature, injection pressure, and clamping force. This helps to ensure consistency and quality in the products being molded. 5. **Energy Efficiency**: - Modern Inovance controllers often focus on optimizing energy usage. They can adjust the machine’s power output based on real-time load, improving energy efficiency and reducing operational costs. 6. **Connectivity & Integration**: - Inovance injection molding controllers often support various industrial communication protocols, such as **Ethernet/IP**, **Modbus**, or **Profinet**, allowing easy integration with other devices and centralized monitoring systems. - Some systems support IoT (Internet of Things) capabilities for remote monitoring and diagnostics. 7. **Safety Features**: - Injection molding machines require high safety standards, especially because of the risks posed by high-pressure hydraulic systems and moving parts. Inovance controllers typically come with built-in safety features such as emergency stop functionality, overheat protection, and more to protect both the operator and the machinery. 8. **Customization and Flexibility**: - Many Inovance controllers offer customizable settings and programming options, allowing manufacturers to tailor the machine’s operation to specific molding processes. This can include setting different modes (e.g., automatic, manual, or semi-automatic) for various stages of the molding cycle. ### Common Models of Inovance Controllers in Injection Molding Machines: - **DVP Series PLCs**: Often used in injection molding applications, these programmable logic controllers (PLCs) are known for their flexibility, ease of use, and reliability. - **Inovance HMI Models**: HMI interfaces by Inovance allow for easy interaction with molding machines. They often feature large screens for visualization of machine parameters and process control. ### Application Benefits: - **Improved Production Efficiency**: Optimized injection cycles reduce downtime and improve throughput. - **Enhanced Product Quality**: Real-time feedback and precise control parameters ensure consistent molding results with minimal defects. - **Ease of Maintenance**: The system can alert operators about potential issues, minimizing unplanned downtime and ensuring preventative maintenance. ### Conclusion: If you\'re working with an **Inovance injection molding machine controller**, you’ll be benefiting from an advanced automation solution designed for efficiency, safety, and precise control. The controllers are highly customizable, making them suitable for a wide range of injection molding processes. You’ll likely find various options for monitoring, data collection, and connectivity, which are essential for maintaining high-quality production while also minimizing energy consumption.

2025-01-24T09:32:36

Keywords

- inovance controllers

- controllers operators

- machine parameters

- wide range

- machinery 8 customization

- algorithms optimize

- typically find

- automation products

- manufacture controllers

- alert operators

- key parameters

- machine health

- youre working

- easy interaction

- flexibility ease

- automatic manual

- risks posed

- things capabilities

- ethernetip modbus

- clamping force

- material waste

- easily interact

- userfriendly interfaces

- movements efficiently

- key details

- machines operation

- control settings

- efficiency safety

- ensure consistency

- remote monitoring

- precise control

- realtime monitoring

- molding machines

- injection process

- ensure stable operation

- require precise control

- injection molding machines

- monitoring realtime feedback

- injection molding process

- minimal defects ease

- builtin safety features

- monitoring data collection

- centralized monitoring systems

- injection molding applications

- injection molding packaging

- specific molding processes

- minimizing energy consumption

- maintaining highquality production

- highly customizable making

- feature large screens

- highpressure hydraulic systems

- industrial communication protocols

- optimizing energy usage

Submit Your Enquiry